Capabilities

Penn Compression is a full-service thermoset custom molder. Let us know how we can help.

Engineering / Conversions

Penn has engineering and project management experience and expertise to help drive your application to successful commercialization. High performance thermoset composites provide:

- Superior physical performance

- Dimensional stability

- High-temperature performance

- UV resistance

- Lower costs

- Lightweight

- Corrosion resistance

- Chemical resistance

- Molded in color

Custom Molding

Penn Compression has over 70 molding presses from 50 tons to 750 tons including compression, transfer and injection machines.

Penn handles a wide range of thermoset materials including polyester, vinyl ester, phenolic, melamine, epoxy, DAP, urea and more in a variety of forms such as bulk molding compound (BMC), sheet molding compound (SMC), thick molding compound (TMC), prepregs and powder.

Penn also provides insert molding and overmolding.

Secondary and Finishing

Penn Compression provides a full range of secondary and finishing operations including:

- Drilling and tapping

- Post curing

- Bonding

- Testing

- CNC machining

- Painting

- Assembly / Sub-assembly

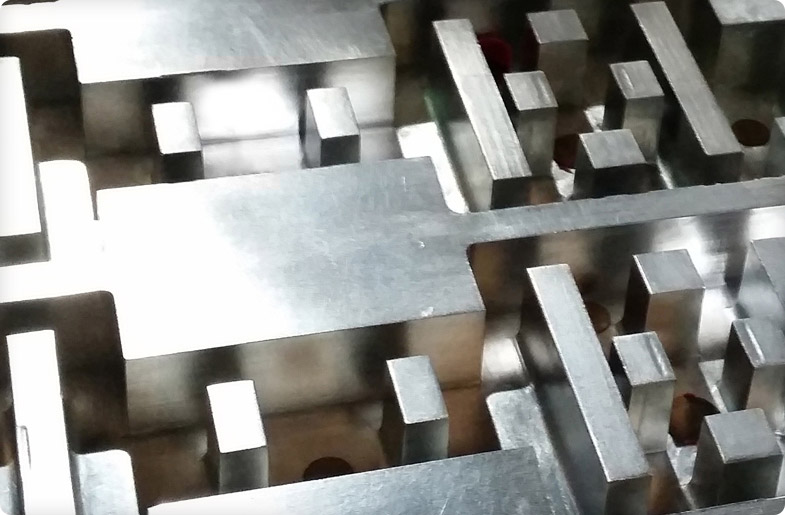

Tooling

Penn Compression provides full tooling support for production and prototype tooling including tooling design, manufacture, sourcing, program management and repair.

Penn can help source molds domestically and from lower-cost regions such as Asia.

Quality

Penn Compression is committed to providing high-quality products and services through a quality system that is ISO 9001:2015 certified.